Medical Lox and Lin Production Plant Liquid Oxygen Nitrogen Plant

Basic Info

| Model NO. | NZ-G |

| Condition | New |

| Certification | ISO, CE, CCC |

| Product Name | Air Separation Gas Generation Plant for Steel Fact |

| Place of Origine | Zhejiang, China |

| Warranty | 1 Year |

| Video Outgoing-Inspection | Provided |

| Core Components | PLC, Motor |

| Dimension(L*W*H) | Capacity |

| Purity | 90-99.999% |

| Material | Carbon Steel |

| Keyword | Liquid Oxygen & Nitrogen Plant |

| Transport Package | by Container or Bulk Cargo |

| Specification | As design |

| Trademark | Nuzhuo |

| Origin | Zhejiang, China |

| HS Code | 8419609090 |

| Production Capacity | 50-3000nm3/H |

Product Description

China Air Separation Gas Generation Plant For Steel FactoryProduct Name | Liquid oxygen & nitrogen generator | |||

Model No. | NZDON- 5/10/20/40/60/80/CUSTOMIZED | |||

Brand | NuZhuo | |||

Accessories | Air compressor & Refrigerated unit &Turbo Expander & Fractionating column | |||

Usage | High purity Oxygen & Nitrogen & Argon production machine | |||

| Details of Nuzhuo ASU Series |

Air Compressor : Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa). It is done by using the latest compressors (Screw/Centrifugal Type).

Pre Cooling System : The second stage of the process involves use of a refrigerant for pre-cooling the processed air to temperature around 12 deg C before it enters the purifier.

Purification of Air By Purifier : The air enters a purifier, which is made up of twin molecular Sieve driers that function alternatively. The Molecular Sieve separates the carbon dioxide & moisture from the process air before the air reaches at air separation Unit.

Cryogenic Cooling of Air By Expander : The air must be cooled to sub zero temperatures for liquefaction. The cryogenic refrigeration and cooling is provided by a highly efficient turbo expander, which cools the air to temperature below -165 to-170 deg C.eparation of Liquid Air into Oxygen and Nitrogen by Air Separation Column : The air that enters the low pressure plate fin type heat exchanger is moisture free, oil free and carbon dioxide free. It is cooled inside the heat exchanger below sub zero temperatures by air expansion process in the expander. It is expected that we achieve a difference delta as low as 2 degree Celsius at the warm end of exchangers. Air gets liquefied when it reaches at the air separation column and is separated into oxygen and nitrogen by the process of rectification.

Liquid Oxygen is Stored in a Liquid Storage Tank : Liquid oxygen is filled in a liquid storage tank that is connected to the liquefier forming an automatic system. A hose pipe is used for taking out liquid oxygen from the tank.

| Package And Shipping |

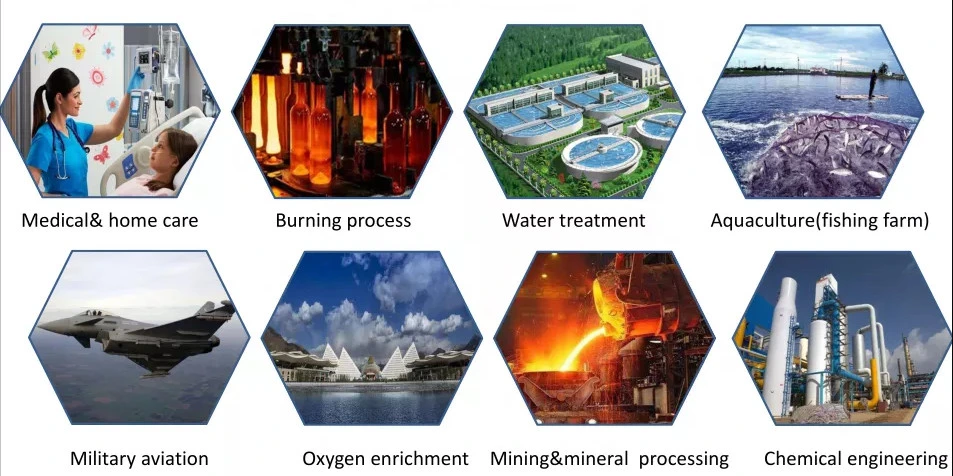

| Applications For The ASU |

Through the industries we serve below, you'll see how Nuzhuo helps customers do more with less. Refining, Healthcare, Aerospace Laboratories, Diving, Food & Beverage, Medicine & Biotechnology, Electronics, Oil & Gas, Water & Wastewater, Energy, Metal Production, Welding & Metalworking Chemicals, Pulp & Paper, Automotive and Transportation Equipment, Glass Manufacturing

gases and medical gases.

Hangzhou NuZhuo Technology is a professional manufacturer of cryogenic air separation, VPSA

oxygen production device, compressed air purification device, PSA nitrogen production, oxygen

production device, nitrogen purification device, membrane separation nitrogen production and oxygen

production device, electric. Pneumatic control valve. Temperature control valve. Cut off valve production

enterprises.

Welcome to visit our factory. Our factory address:

No. 88, East Zhaixi Road, Jiangnan Town, Tonglu County, Hangzhou City, Zhejiang,China.